by Doug Morgan | Sep 4, 2023 | HVAC

Stay cool in Tampa with the ultimate portable air conditioner! If you’re tired of feeling uncomfortable due to the hot and humid weather, a portable AC unit may be the perfect solution. In this blog post, we’ll answer the question of how long you can run a...

by Doug Morgan | Aug 21, 2023 | HVAC

If you’re in the market for a new AC unit, it can be overwhelming to navigate through the many different brands and types available. From American Standard to split AC units, window ACs, and wall-mounted units, there are a plethora of options to choose from....

by Doug Morgan | May 18, 2023 | A/C Unit, HVAC

Living in Tampa, Florida means dealing with high temperatures and humidity levels for the better part of the year. A reliable air conditioning system is essential for keeping your home comfortable and healthy. Whether you’re installing a new AC unit or upgrading...

by Doug Morgan | Apr 3, 2023 | HVAC

Living in Tampa, Florida, we all know that the summer months can be incredibly hot and humid. The sweltering heat can make it challenging to stay comfortable indoors, and high humidity levels can cause a range of problems, from mold and mildew growth to physical...

by Doug Morgan | Apr 3, 2023 | A/C Unit, HVAC

Welcome to our blog post, where we will help you Beat the Heat and fix your air conditioning problems fast! As an expert from National Air Warehouse and a local of Tampa, FL, I understand the importance of having a reliable air conditioning unit, especially in hot and...

by Doug Morgan | Mar 25, 2023 | HVAC

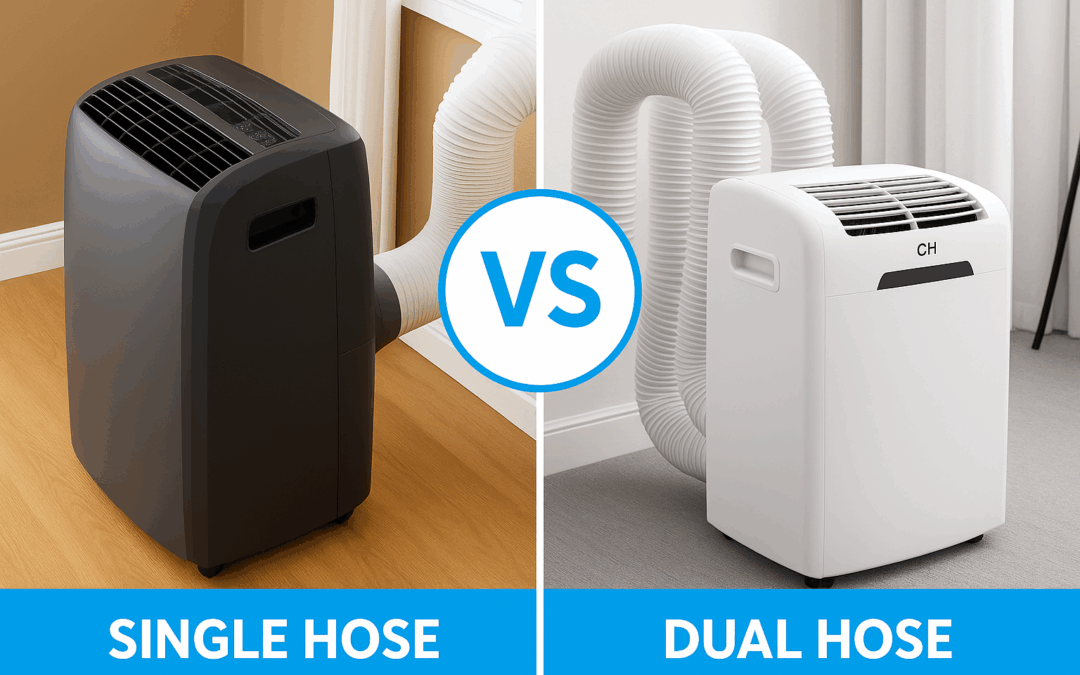

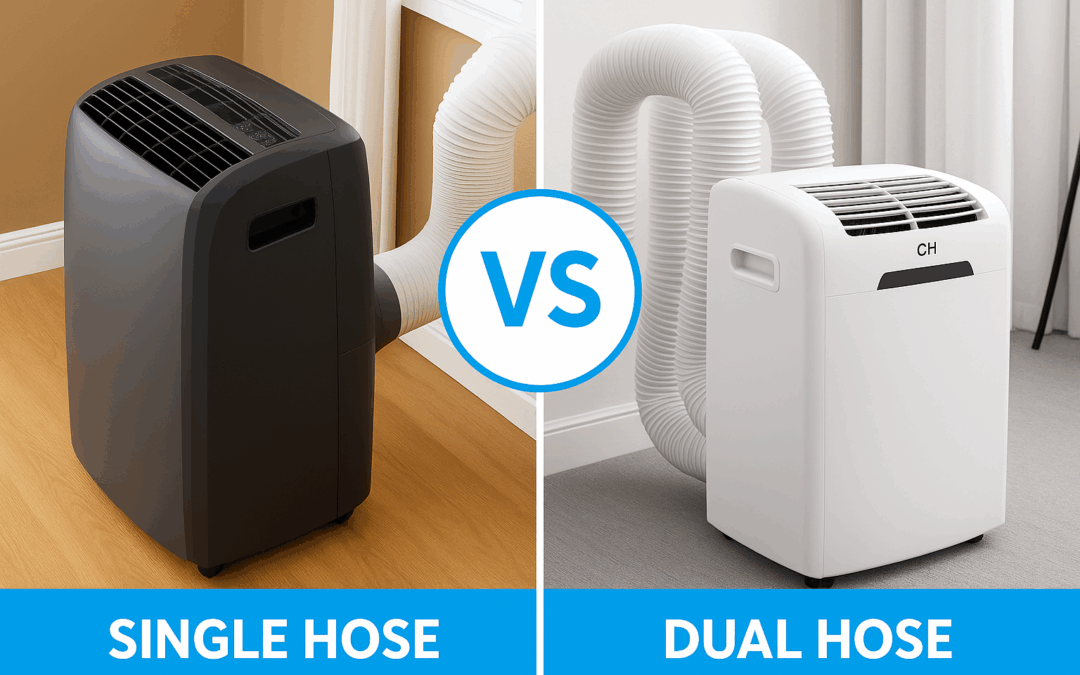

Understanding the Fundamental Difference Between Vented vs Ventless Portable Air Conditioners Choosing between vented and ventless portable air conditioners can make or break your cooling experience. While both offer portability and convenience, they work in...

by admin | Apr 3, 2018 | Heating System, HVAC, National Air Warehouse

In last week’s post, we talked about some of the functional and cost-related benefits that programmable thermostats offer for businesses. Once you’ve made the decision that a programmable thermostat is right for your business, you’re faced with a wide array of...

by admin | Mar 6, 2018 | HVAC, National Air Warehouse

Mobile homes are on the rise in the United States. In 2016 alone, over 81,000 mobile homes were sold and shipped, which was a 15 percent increase over 2015. According to the latest survey data, there are seventeen states in which at least one out of every ten housing...

by admin | Jan 23, 2018 | Heating System, Home Temperature Control, HVAC

If home builders can learn anything from the winter of 2017-2018, it’s that an effective heating systems is essential for a comfortable home. As temperatures have dropped to record lows around the country, home builders need to be aware that more clients will be...

by admin | Jan 16, 2018 | Heating System, HVAC, National Air Warehouse

When you are remodeling a home or office building, you need to make sure that the gas furnace is sufficient to guarantee a comfortable temperature throughout the newly remodeled space, no matter how cold the winter weather gets. However, things can get tricky if you...